W.O. PROJECT

Overview

Arctic Blue holds a 89.7% interest in the WO Joint Venture (WO JV) with DHK Diamonds Inc. (10.3%) holding a participating minority interest. Arctic Blue is the operator of the WO JV.

The WO Project is located 23 km from the Diavik Diamond Mine, 53 km from the Ekati Diamond Mine and 11 km off the seasonal ice road that services the diamond mines. The WO JV holds eight mining leases covering approx. 5,800 hectares.

In 1993, a subsidiary of Rio Tinto discovered five kimberlites at the WO Project, including DO27, DO18, DO29, DO32 and AD02. In 1998, further drilling at the DO29 kimberlite proved it to be two separate kimberlites (DO29N and DO29S). Between 2002 and 2012, three additional kimberlites were discovered (WO9, LD2 and LD3), bringing the total number of kimberlites at the WO project to nine.

Following discovery, advanced exploration was conducted on the DO27 and DO18 kimberlites, with the focus being on the DO27 kimberlite.

DO27 KIMBERLITE

DO27 Kimberlite Deposit

DO27 is one of the largest diamondiferous kimberlite pipes in Canada. The pipe has a surface area of approx. 9 hectares and lies below a shallow lake with an average depth of approx. 4m and area of 1km². By comparison, all the kimberlites mined at the Diavik Diamond Mine have surface areas less than 2 hectares and most of the kimberlites at the Ekati Diamond have surface areas less than 3 hectares.

Extensive delineation and resource drilling has been undertaken at DO27, including 114 core holes (24,185m) and 46 large diameter reverse circulation holes (8,840m). DO27 has been explored in detail to a depth of approx. 350m and it remains open further to depth.

Based on drilling completed to date, the DO27 kimberlite hosts the following Mineral Resources:

| Tonnes (1,000,000s) | Carats (1,000,000s) | Grade (cpt) | |

| Indicated Mineral Resource | 19.5 | 18.2 | 0.94 |

Notes:

- Effective date is August 7, 2008

- Dr. Ted Eggleston, RM SME and Ken Brisebois, P.Eng. are the Qualified Persons for the estimate.

- Mineral Resources are stated at an effective 1mm bottom cutoff and are constrained within a conceptual mining shell based on assumptions of a diamond price of US$72/carat, 100% metallurgical recovery, US$2.05/t mining costs with an incremental $0.02 per 10m depth, US$19.96/t operating costs including on-site scrubbing and an estimate for trucking to, and processing at, an off-site diamond processing facility.

At depth, beneath the Indicated Mineral Resource, an additional 6.5-8.5 Mt of kimberlite grading in the range of 0.8-1.0 carats per tonnes (cpt) represents a target for further exploration. The potential quantity and grade of this target is conceptual in nature. Further exploration will be required to define an expanded mineral resource. It is uncertain whether additional exploration will result in the target being delineated as a mineral resource.

DO27 Diamond Valuations

Independent valuations of diamonds recovered from DO27 were conducted in 2006 and 2007 by WWW International Diamond Consultants Limited (“WWW”). The 2007 valuation was based on a parcel of 2,075 carats. The DO27 Mineral Resource declared in 2008 assumed an average diamond price of US$72 per carat. In July 2014, WWW provided a report showing a general upward trend to diamond prices since the 2007 valuation. Based on independent rough diamond price indices, the average diamond price for the DO27 parcel is now projected at US$90-100 per carat.

Underwater Remote Mining Technology

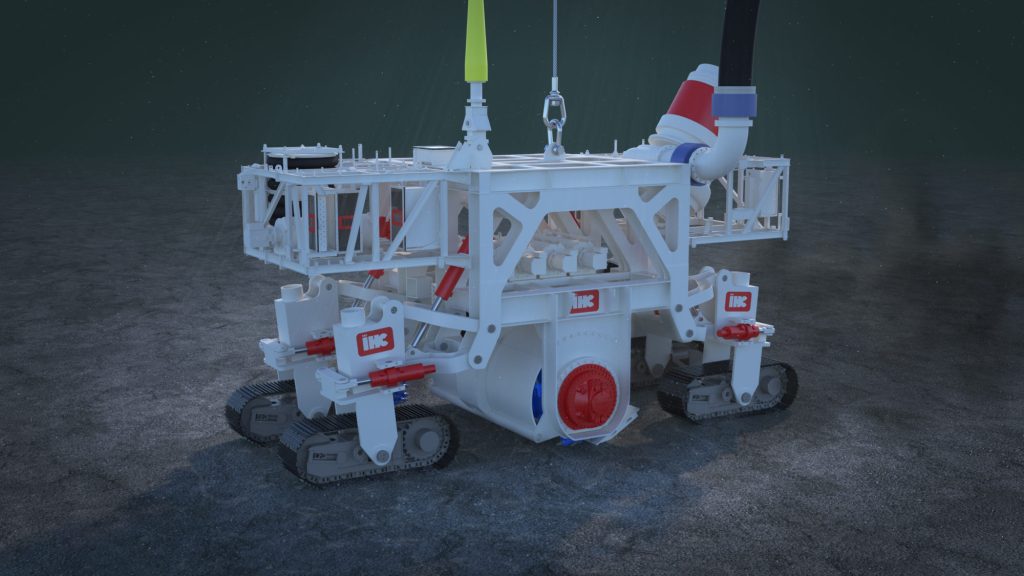

Underwater Mining Crawler concept. Source: IHC Mining

Traditionally, kimberlite pipes have been mined as open-pits or underground mines, both requiring high capital and operating cost support. The nature of the DO27 kimberlite makes it ideal for deployment of Underwater Remote Mining (URM) technology. Kimberlites like DO27 that have soft, low-density ore can be mined most efficiently using URM systems. Besides offering exceptionally low capital and operating cost opportunities, URM is the most sustainable form of mining with minimal impact on the environment.

The URM system for kimberlites was developed by IHC Mining, a division of Royal IHC (“IHC”) of The Netherlands, and is based on decades of deep-sea mining and trenching experience. In 2018, while CEO of Dominion Diamonds, Arctic Blue Diamond chairman Patrick Evans contracted IHC to develop an URM system for deployment at the Ekati Diamond Mine in Canada’s Northwest Territories. Over the past seven years, various elements of URM systems have been tested and capital and operating costs have been modeled. The test results confirmed that the most suitable system for underwater kimberlite mining is the “Crawler” system.

As announced by IHC Mining on September 14, 2022: “The underwater mining crawler is a remote operated continuous mining machine, equipped with the latest underwater control and positioning equipment. The ore is directly excavated with a drum cutter in small layers and eliminates the need for blasting explosives. From the crawler the ore is pumped to the surface of the flooded pit via a vertical pipeline system to the Launch and Recovery Platform, from where the ore is transported further to a dewatering plant. The crawler system is capable of operating at a water depth of up to 400 meters.”

The Ekati Diamond Mine’s first mining crawler has been built at IHC’s facility in the United Kingdom. Ekati plans to test the launch and recovery platform that supports the mining crawler, followed by a trial mining with the URM crawler at the Lynx Kimberlite with the goal of extracting 150,000 tonnes of kimberlite. On completion of the trials, the entire URM crawler system will be deployed for commercial production at Ekati.

A video demonstrating the URM technology can be found here.

Kimberlite Ore Concentrate Option

Based on the extremely soft, low-density nature of the DO27 kimberlite, an Ore Concentrate Option has been developed whereby a simple ore washing process removes high quantities of unwanted fines fractions below 1mm and retains the +1mm ore fractions for final processing at an existing off-site diamond plant. Testing of the DO27 kimberlite has confirmed that approx. 90 percent of the ore in the first 60m depth interval will report to fines after the washing process. This significantly reduces the volume of diamond-bearing ore to be transported to an existing off-site diamond plant.

Potential Impact on Environment, Capital, and Operating Costs

Conceptual studies confirm that the combination of the URM system and ore concentrate option will significantly reduce the environmental impact of a DO27 mining operation as well as projected capital and operating costs. Key areas for significant cost efficiencies include:

- significantly reduced workforce;

- reduced fuel and fuel storage requirements (no mining fleet);

- reduced heavy equipment workshop;

- no waste rock management facility (no waste stripping);

- reduced processed kimberlite containment facility (offsite treatment);

- reduced water management facilities;

- no diamond recovery plant (eliminates ore crushers, DMS circuits, thickener circuits,

- diamond recovery circuit, etc.);

- reduced camp and support facilities;

- no diamond security control centre;

- reduced power generation requirements; and

- reduced warehouse and storage facilities.